Why choose South Eastern Gaskets

South Eastern Gaskets is a third-generation family-owned and operated business that has been providing high-quality gaskets, seals, washers and various other parts since 1974. Starting from humble beginnings in the backyard of the family home, we have grown to become a leading manufacturer in the industry.

With two complete factories located in Braeside, Victoria and Lonsdale, South Australia, we manufacture and stock a wide range of products. All our parts exceed the standards of ISO 9001:2015 and are made to meet and exceed the expectations of our customers.

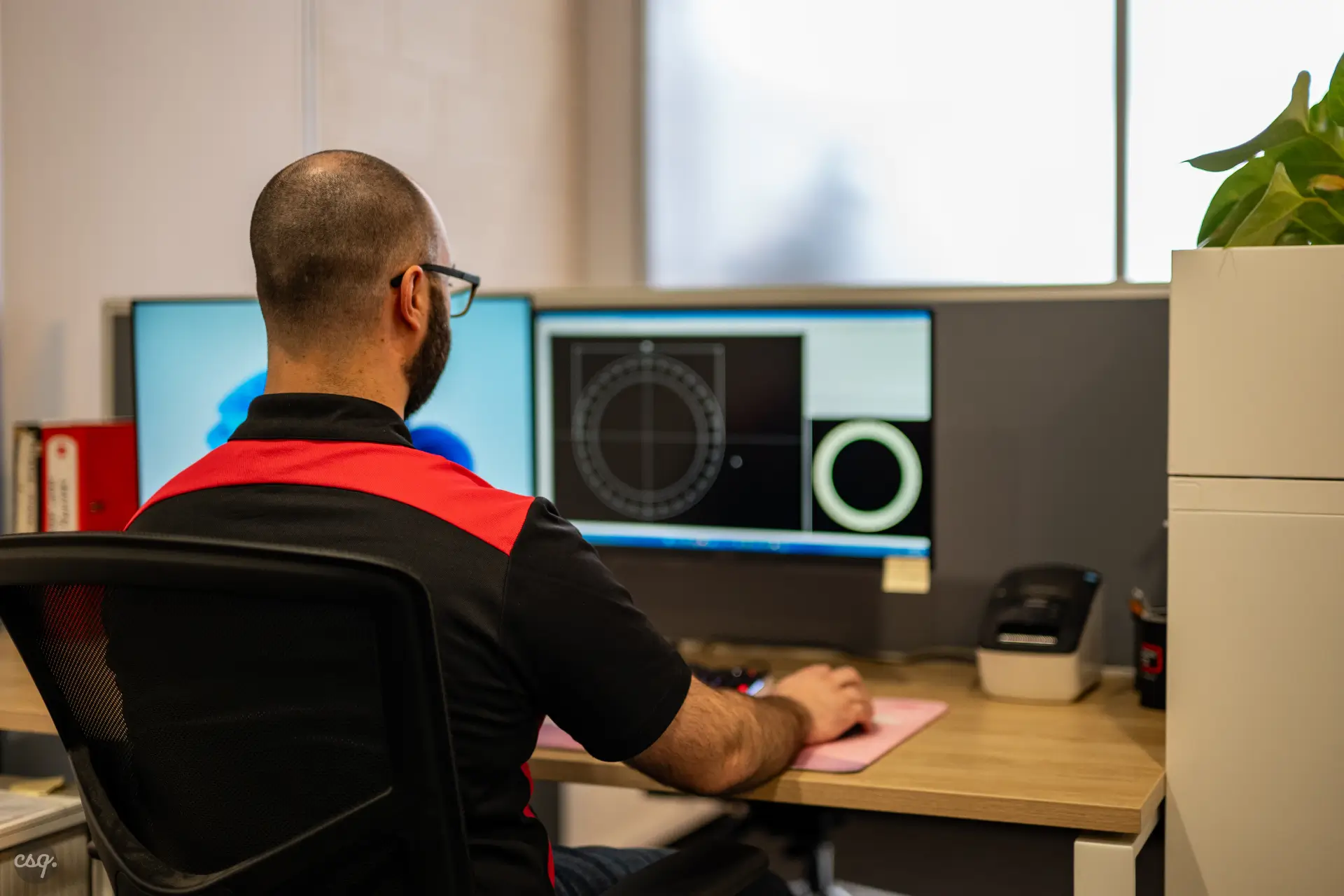

Our manufacturing facilities are equipped with modern technology and a range of presses and tools so we can produce a large variety of materials and gaskets for all types of industries.

Our range of products includes:

- Cork

- Plastics

- Packing

- Felt

- Sponge

- Corr-a-seals

- Spiral wounds

- All types of rubber (Viton, silicone, nitrile, EPDM, natural, and insertion)

At our company, we are committed to providing excellent customer service. Our professionally trained employees are always ready to help and ensure that our customer’s requirements are met within a short time frame. Our consistent, high level of quality and customer service is the reason for our steady and continued growth.

We service a wide range of industries such as:

- Chemical

- Water treatment

- Irrigation

- Air conditioning

- Pump and valve manufacturers

- Pharmaceutical

- Defence

- Marine

- Medical

- Automotive

With our large product range and modern production facility, we are confident that we can provide solutions to all your sealing requirements. Contact us today to experience the professionalism and experience of a company that prides itself on producing quality parts for all industries.